Visitors: 12613756 Views

Done By: Department of Prosthetics and Orthotics Engineering

Post Date: 2024-01-10

Last Browse: 2024-11-21

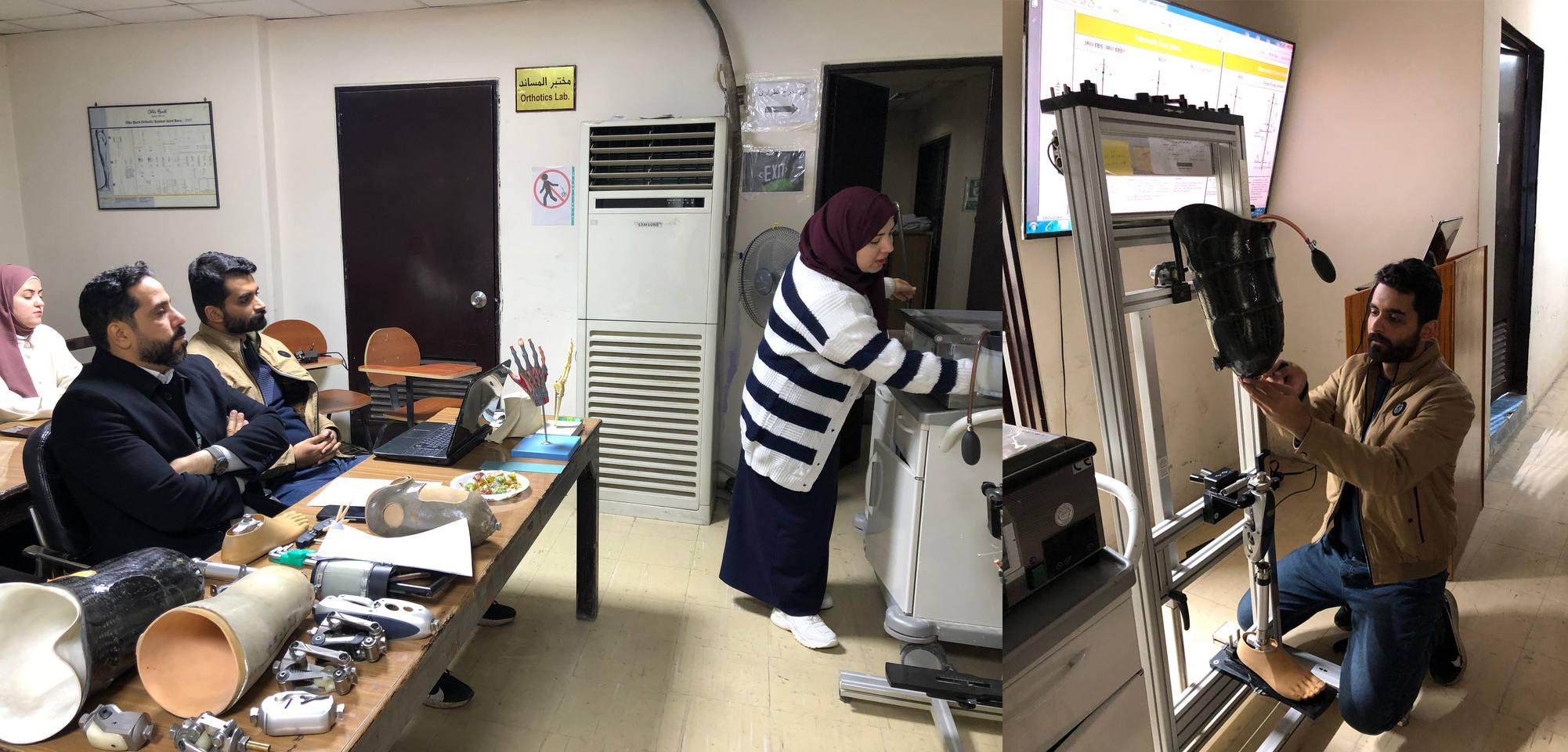

Two successful workshops were recently held in the P&O

Engineering Department at the company. Engineer Jassim Mohammed provided a

detailed explanation of the 743A220 PROS.A. Assembly device and its uses in

assembling industrial limb parts, whether below or above the knee, and creating

ideal interfaces between interconnected parts using official measurements

prescribed by the manufacturer. This device makes the walking cycle smoother

and less strenuous for patients while reducing errors resulting from imprecise

work.

In the second workshop, Engineer Noor delivered a lecture on

the "water bath" device and conducted a practical manufacturing

experiment for a finger support. Engineer Noor Basim explained the

manufacturing steps and their practical application, highlighting the

importance of the device and how it can be used more effectively in the future

in the field of upper support manufacturing. The device is made of

corrosion-resistant steel and operates on the principle of heating water for

molding and shaping a piece of fusible plastic material. The piece is designed

and drawn based on the patient's condition, and after heating, it is extracted

and directly molded on the hand. Subsequently, the focus is on completing the

manufacturing process and taking care of the aesthetic and functional aspects

of the supports.

The workshops demonstrated their ability to transfer

knowledge and teach the necessary skills for accurately assembling industrial

limbs and manufacturing high-quality upper supports with excellence.